News – Blog

Meet the Team: Greyparrot Insight (11/10/24)

October 11, 2024

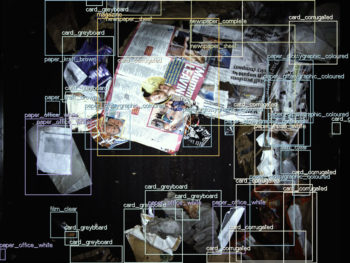

Meet the team behind Greyparrot Insight, an AI waste analytics system capable of ‘seeing’ and tracking waste through sorting and recycling plants.

Materials recovery facilities (MRFs) are the final fork in the road between a resource being recycled, or sent to landfills and incinerators. MRFs perform the vital task of redirecting material back to the Meet the team behind Greyparrot Insight, an AI waste analytics system capable of ‘seeing’ and tracking waste through sorting and recycling plants.

In the last few decades, tools like optical sorters, mechanical balers, and air jet separators have introduced automation to MRFs, helping them keep pace with the rising level of waste. However, a spike in global consumption in recent years means we’re throwing away more recyclable material than current manual or mechanical systems can effectively recover. By 2050, the world is predicted to generate 3.8 million tonnes of municipal solid waste every year. Municipal solid waste refers to all the everyday rubbish we throw away, like food scraps, packaging, broken furniture, and other household items. Through embracing the use of AI in our waste flows, we can more accurately sort refuse and reduce recyclable materials going to landfills.

Greyparrot are finalists in the first round of the Manchester Prize, using the Prize to continue their work in developing a complete digital map of the UK’s waste flows. Through tracking discarded waste, Greyparrot looks to improve recycling rates and make recommendations for packaging design.

A growing waste data gap

New technologies have streamlined various aspects of waste management from sorting to baling, yet facility operators have largely remained reliant on manual counting to gather waste data. Currently, the average recovery facility measures just 1% of the waste it receives. As the saying goes, “You can’t manage what you don’t measure.” This lack of comprehensive data limits the potential for improving recycling rates. With facilities expected to process more mixed materials each year and each waste stream being unique, gaining better insight from MRFs is critical.

“Participating in the Manchester Prize has been a tremendous stepping stone for Greyparrot. The Prize supported us with essential compute credits, allowing us to accelerate our AI research and development. Attending sessions with DSIT’s Responsible Technology Unit on ethics has enriched our understanding and approach to building responsible AI solutions. And more broadly, we have been fortunate to join a variety of excellent sessions that have spanned commercial topics, as well as connecting to relevant industry and public contacts. Greyparrot is a stronger business for it and, as a result, the Prize has accelerated our path to social impact.”

– Harry Davies, Chief of Staff, Greyparrot

A growing waste data gap

New technologies have streamlined various aspects of waste management from sorting to baling, yet facility operators have largely remained reliant on manual counting to gather waste data. Currently, the average recovery facility measures an average of 60kg for every 75 tonnes of incoming waste received, meaning only 1% of the waste is being sampled. As the saying goes, “You can’t manage what you don’t measure.” This lack of comprehensive data limits the potential for improving recycling rates. With facilities expected to process more mixed materials each year and each waste stream being unique, gaining better insight from MRFs is critical.

“AI waste analytics unlocks unprecedented insight about the materials we throw away, marking an exciting turning point in our relationship with resources.”

– Alisa Pritchard, VP of Marketing for Greyparrot

Enhanced data analysis can begin to understand complexity, improve material separation, and ultimately lead to higher recycling rates. Plastic alone accounts for 350 million tonnes of waste material annually, but a lack of visibility to allow accurate sorting of waste flows means that just 9% of it is recycled around the world.

How AI can unlock visibility in waste management

AI waste analytics systems like Analyzer, Greyparrot’s camera unit, combine computer vision with automated data analysis, facilitating the collection of real-time information on waste flows, at scale. AI waste analytics systems collect and organise vast amounts of waste data, paving the way for what Greyparrot call “waste intelligence”. Greyparrot Analyzer enhances visibility into waste streams by automatically identifying and tracking waste objects at a rate 62 times faster than manual counting. Its compact hardware allows facilities to integrate the system painlessly into sites’ existing infrastructure without requiring adjustments. In 2023 alone, Greyparrot’s systems analysed over 25 billion waste objects, a number that increases with each new Analyzer that their customers deploy.

“Waste intelligence is the actionable insight gathered from detailed waste data, used to minimise waste and optimise resource use. Waste intelligence translates waste data into tangible action of improving resource efficiency across the value chain.”

– Alisa Pritchard, VP of Marketing for Greyparrot

With access to detailed waste data, operators are supported to adjust their operations in real-time as waste flows shift. This enables them to optimise processes, extract more value from recyclable materials, and reduce the volume of waste material sent to landfills and incinerators.

Greyparrot’s technology also has other benefits, including:

- Finding the optimum balance between productivity and resource recovery. The faster facilities process waste, the more value they tend to lose to landfills. A live data feedback loop helps them fine-tune operations for both efficiency and material recovery.

- Proactively maintaining hardware. Facility performance data enables operators to make a business case for investment, and target staff training where needed, before further issues arise.

- Tailoring sorting processes to specific suppliers. When producing high-quality recycled material, input matters. Operators can analyse the material they receive from suppliers, source higher-quality bales, and adopt specialised sorting processes.

Optimising sustainable packaging production with waste intelligence

Brands and retailers make significant investments in tracking consumption, sales trends, and logistics to enhance production processes. In comparison, post-consumption insights remain a ‘dark abyss’, with knowledge of a product’s life-cycle ending the moment the consumers throw the products away.

Waste intelligence insights gathered in global recovery facilities present an opportunity to unlock the hidden value within global waste streams for:

- Brands grappling with regulations like extended producer responsibility (EPR) and plastics taxes that will need to innovate to develop more sustainable products. Post-consumption insight identifies areas for improvement to remain compliant.

- Product designers who contend with technically recyclable materials that still end up in landfills. Waste intelligence can pinpoint under-recovered products, informing design enhancements that boost packaging recyclability.

- Regulators who can use waste intelligence to assess compliance, target problematic materials, and evaluate policy effectiveness to craft impactful regulation.

“Across 50+ facilities in over 20 countries, plant managers are using waste intelligence insights to recover more material, more profitably. At Re-Gen Waste’s flagship materials recovery facilities, Analyzer data ensures that recycled fibre products meet the quality standards required to provide a viable alternative to virgin paper production.”

– Alisa Pritchard, VP of Marketing at Greyparrot

To take action on waste, producers and regulators will need to work closely with the facilities that are processing it. The waste sector is now at the heart of a collaborative value chain relying on data to use resources as efficiently as possible and minimise their impact on the environment. Many innovative recovery facilities are already using live waste data to improve their operations – with measurable results. In the process, they’re also gathering information on post-consumption material that, over time, is poised to transform the entire value chain.