News – Blog

Meet the Team: AssetScan

December 16, 2024

Meet the team behind AssetScan, using image-to-image processing techniques to detect changes in structure conditions and target effective maintenance at the earliest opportunity.

Whilst it may not be easy to notice defects on the UK’s large and ageing infrastructure; these defects are very prevalent . If defects are allowed to continue to develop without repair, it can lead to rail and road closures, failed supply of water and other services, or public safety incidents.

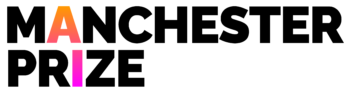

AssetScan is an AI solution that, when combined with large numbers of photos taken by drone, can assist asset managers and engineers by locating infrastructure defects and cataloguing them in a way that is simple to interpret. Inspecting large structures is difficult. Furthermore, practices to inspect infrastructure have remained unchanged and ineffective for centuries. Current defect detection techniques largely rely on the judgement of an experienced engineer, handwritten notes, and in more recent years some cataloguing with the use of photographs. For very large structures, it would not be unusual to take a pair of binoculars on site.

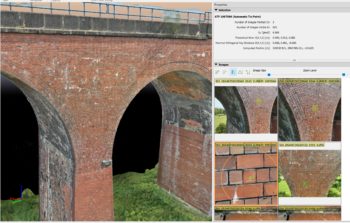

“Drones are an excellent method of survey, because it removes the human element that would be at risk. Rather than using rope access, a drone can get up there very easily and very quickly, and record accurate details at close distances. More data is always better, and higher quality data means a higher quality output. For a structure as large as [Whalley Viaduct] – going into fine detail, say to the level of individual bricks, remembering that this structure has more than 2 million bricks – working out the required repointing or recasing works would take weeks or months of work, and could be undertaken in a few days by an AI. What we are excited to get from AssetScan is accurate 2D drawings and 3D models.”

– Alex Treanor, Network Rail Internal Design Team

There are numerous issues that hamper detection of structural defects and issues that need repairs:

- Limited Visibility – Engineers can’t always inspect defects clearly if they are located in areas that are challenging to view or examine

- Environmental Constraints – Certain structures may not be inspectable during daylight and adverse weather conditions can further hinder visibility and accuracy.

- Inconsistency in Documentation – When an engineer sees a type of defect for the first time, it will be documented in great detail. Once the engineer observes many examples of a defect, it will simply be referred to as ‘occurring everywhere’.

- Subjective Judgement – Some engineers know more or less about different defects. Some are more or less conservative in their approach to documenting defects. This can introduce additional bias and error.

- Lack of Contextual Background – When a defect is noticed, it may be documented in detail, but if it is new or the first time it has been seen, then it is unlikely a good record of the prior conditions exists in this exact location.

- Tracking Defects – Inspections of ageing and large assets are required to keep them functioning. After inspections, maintenance schedules can be put together to ensure that defects, where they are documented, are remedied and that additional investigation and analysis are undertaken where appropriate. The issues above hamper maintenance efforts – and so a more consistent means of identifying and tracking defects would be greatly beneficial.

AssetScan

AssetScan, is a machine vision product that can be used to look for defects in structures. The AssetScan algorithm has been designed to scale; making it possible to include new materials and types of defects over time. The technology works with large quantities of photographic data, such as images captured by a drone survey.

The algorithm works first by segmenting the photos – identifying which parts of the photograph are likely to contain a structural material, and if so, what type. This is then assessed by more machine vision algorithms, each looking for a particular defect in a particular material – for example; cracks in concrete, or loss of mortar from brick walls.

The original images can subsequently be used to build a 3D model of the structure. The results generated from the AI software are then projected onto the model, and used to build 2D engineering drawings containing defect information. This information can also be used to generate tables of defect information for engineers to use.

Improved understanding of the locating, type, size, and rate of growth of defects is essential in planning effective maintenance. Without this, planned improvements and remediation may fail to address the issues. This can lead to outages – like a bridge being closed to vehicles of a certain weight, or pipelines being isolated from passing water. AssetScan looks to improve the quality of asset inspection, and by extension, improve the resilience of the UK’s large infrastructure.

Outages can create significant problems for the public, extending beyond delays or traffic during rush hour. An outage can prevent vulnerable people from getting access to services that they need. For example, without resilient transport infrastructure, people may lose access to their healthcare providers and some communities could even become completely isolated.

AssetScan also supports engineers. The use of remote photographic surveys,removes engineers from out of risky situationssuch as working from heights, or in confined spaces. However to date, these surveys produce too much data (perhaps thousands of high resolution photos) with little useful insight. AssetScan makes these surveys easier and quicker to interpret – and therefore makes remote methods more feasible. With increased adoption, this can reduce the probability of workplace casualties or fatalities.

Beyond the health and safety implications, AssetScan can also help increase the productivity of engineers. Rather than spending a lot of time reviewing drone surveys, AssetScan frees engineer’s time, by producing a collated list of defects in an order that can be ranked. After this, the engineer only needs to verify that the AI has correctly identified a defect, rather than search for it themselves. This also means that engineers can plan more maintenance, more efficiently.

“Manchester Prize has brought more credibility to our work, particularly in advancing our talks and building our industry connections. This has been particularly useful in establishing our ongoing partnership with Network Rail. Furthermore, the prize has allowed us to be more visible with probably the hardest markets to get into in the UK, so even if we don’t win the 1 million pound grand prize, we are in a much stronger place to go forward and go further for investment”

– Rhys Coombs, Co-Founder, CC Informatics

Whilst AssetScan’s development team is small, they have extremely diverse experience. Within the team we have experience of dams, reservoirs, hydropower, simulation, flood defences, wet infrastructure, geospatial data analysis, marine engineering, films and special effects, game design, robotics, software development, and more.

AssetScan is already in part proven on a range of structures – including Claerwen Dam, Loch Arklet Dam, Sellafield, and Dinorwig Powerstation. If you’d like to find out more, please don’t hesitate to connect with the team.

All images are owned by CC informatics